CORTEST

Address: 38322 Apollo Pkwy, Willoughby, Ohio 44094, USA

Address: 38322 Apollo Pkwy, Willoughby, Ohio 44094, USA

Phone: 440.942.1235

Phone: 440.942.1235

Website: https://cortest.com/

Website: https://cortest.com/

Membership: Silver

Membership: Silver

Description

Cortest has been the industry leader in providing high quality corrosion and materials testing equipment for over four decades, since 1977. The company has an unrivalled reputation as a supplier of custom test systems, having successfully completed some of the most challenging projects in the field.

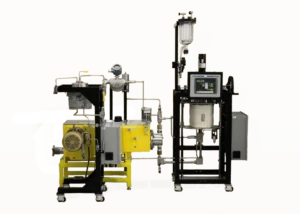

With an extensive history in the testing industry, Cortest has provided corrosion testing services at its laboratories located in Houston, Texas, Columbus, Ohio, and Sheffield, England. The experience gained in commercial laboratories has significantly improved product design, ensuring safe and efficient operation that meets the specific requirements of researchers. Cortest’s product line has grown exponentially over the years, beginning with the successful Proof Ring Test System in 1977, which met the testing requirements of NACE TM 0177 and was used to determine materials that met the NACE material requirement of MR 0175. Today, the product line includes an impressive range of equipment such as autoclaves, loading frames, fume hoods, flow circuits, deadweight testers, HIC tanks, magnetic drives, controls, software, and specialized equipment. The company’s equipment, explicitly designed to meet industry standard test methods, is considered the gold standard in this field.

Recently, Cortest has partnered with universities and global industry leaders to develop and manufacture safety-focused hydrogen testing systems to perform material integrity assessments in hydrogen within existing laboratories. As part of the effort to reduce our global carbon footprint, the production, storage and transportation of hydrogen as a renewable and sustainable energy source is becoming increasingly important, a closed system was developed to perform hydrogen testing at high pressures and temperatures with all the necessary safety measures. Cortest Hydrogen Test Cabinets are designed to allow hydrogen studies to be performed safely within laboratories. These cabinets are equipped with ATEX certified ventilation fans and an automated valve panel to declassify the area for use with autoclave systems, load frames and DCPD test equipment.

Customers can confidently work directly with Cortest engineers to cost-effectively design a fully customized apparatus to precise specifications using the company’s standard products as a foundation. In addition to individual systems, Cortest frequently supplies new, fully equipped laboratories, including test equipment, fume hoods, safety systems, data acquisition, glassware and other supplies.

Cortest equipment is available with PED, CSA, CE, DOSH certificates and China Special Equipment Manufacturing License (upon request). To ensure the successful operation of Cortest equipment, installation, training and commissioning services are available worldwide.